The inner race of the bearing is fitted on the shaft by means of an interference fit. It prevents the relative rotation and the corresponding wear between the inner race and the shaft.

Tolerances are for shaft diameter and corresponding to this type of interference fit, are given in the manufacturers’ catalog.

Care should be taken to select the fit in such a way that it provides sufficient tightness to give a firm mounting and at the same time, it is not too tight a fit to cause deformation of the inner race and destroying clearance between the rolling elements and the races.

The outer race is also mounted in the housing with an interference fit, but to a lesser degree of tightness than that of the inner race. Insufficient tightness of outer race in the housing seat may cause ‘creep’.

In bearing terminology, creep is a slow rotation of the outer race relative to its seating. It is caused when the shaft is subjected to an external force that rotates and changes its direction.

When two bearings are mounted on the same shaft, the outer race of one of them should be permitted to shift axially to take care of axial deflection of the shaft caused either by thrust load or by the temperature variation.

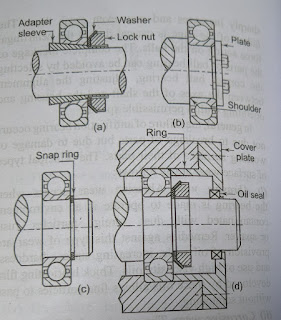

It is necessary to position the inner and outer races axially by positive means. There are several methods such as providing shoulders for the shaft or the housing, locknut, snap ring or cover plates as shown in fig.

|

| Mountings of Bearing |

The basic principle is to restrict the displacement of the inner as well as outer race in the axial direction by positive means.

Fig. (a) shows the mounting suitable for a long and continuous shaft. It consists of an adapter sleeve, which is provided with a smaller taper. The bearing is press-fitted on this adapter sleeve. Because of the taper, the displacement of the inner race to the left side is restricted. A washer and a lock nut are provided to restrict the displacement of the inner race to the right side.

Two methods of restricting the displacement of the inner race are shown in fig. (b) and (c). In both cases, the shaft is provided with a shoulder to restrict the displacement of the inner race to the left side.

In fig. (b), the displacement of the race to the right side is restricted by a plate, which is bolted to the shaft.

In fig. (d), the housing is provided with a shoulder to restrict the displacement of the outer race to the left side.

A circular ring of the cover plate is bolted to the housing. The commercial oil seal unit is used to prevent the leakage of lubricating oil. The shoulder for the shaft and the housing bore have standard dimensions, which can be obtained from the manufacturer’s catalog.

Shafts and spindles in the machine tools and precision equipment should rotate without any play or clearance either in the axial or radial direction.

This is achieved by preloading the ball bearings. The objective of the preloading is to remove the internal clearance usually found in the bearing.

Table of Contents

Preloading of Cylindrical roller bearing

Preloading of cylindrical roller bearing is obtained by the following methods:

- The bearing is mounted on a taper shaft or sleeve, which causes the inner race to expand and remove the radial clearance.

- The outer race is fitted in the housing bore by an interference fit. It causes the outer race to contract and remove the radial clearance.

Ball bearings, such as angular contact bearing are preloaded by axial force by tightening the lock nut during the assembly.

It is essential to use the correct method of mounting and to observe cleanliness if the bearing is to function with satisfaction and achieve the required life.

The precaution to be taken during mounting operation are as follows:

- Mounting should be carried out in a dust-free and dry environment. Mounting should not be carried out in the vicinity if machines that produce metal particles, chips, or sawdust.

- Before assembly, the shaft and the housing bore should be inspected. The burrs on the shaft and the shoulders should be removed. The accuracy of the form and dimensions of the shaft and bearing seat in the housing should be inspected.

- The bearing should not be taken out from its package until before it is assembled. The rust inhibition compound on the bearing should not be wiped except on the outer diameter and bore surface. These inner and outer surfaces are cleaned with white spirit and wiped with a clean cloth.

- Small bearings are mounted on the shaft with the help of a small piece of tube or ring. Blows are applied by means of a hammer on this tube or ring. Direct blows should never be applied to the bearing surface otherwise the race or the cage may get damaged. The tube or the metallic ring is placed against the inner race and the blows are applied with an ordinary hammer all around the periphery of the ring.

- Medium size bearings are mounted on the shaft by pressing the tube or the metallic ring by means of a hydraulic or mechanical press. Large-sized bearing is mounted by heating them to 80 to 90-degree Celcius above the ambient temperature by induction heating and then shrinking it on the shaft. The bearing should never be heated by direct flame.

The interference fit between the outer race and the housing is obtained by similar methods.

Excellent post. I was checking continuously this weblog and I am

impressed! Very helpful information specifically the last phase :

) I deal with such information a lot. I was seeking this certain information for a long time.

Thank you and best of luck.

Hey there are using WordPress for your blog platform?I’m new to the blog world but I’m trying to get started and create my own. Do you needany coding expertise to make your own blog?Any help would be greatly appreciated!

An intriguing discussion is worth comment. I do believe that you

should write more on this issue, it might not be a taboo matter but generally folks don’t speak about these subjects.

To the next! Kind regards!!

Amazing! Its truly remarkable piece of writing, I have got much clear idea about from this post.

You really make it seem so easy with your presentation but I findthis matter to be actually something that I thinkI would never understand. It seems too complex and very broad for me.I’m looking forward for your next post, I’lltry to get the hang of it!